Understanding the performance dichotomy between Spees (Specialty Powertrains & Electric Engines Systems) and traditional internal combustion engine (ICE) vehicles necessitates a nuanced exploration rooted in engineering advancements, environmental considerations, and evolving consumer expectations. As electrification technology matures and regulatory landscapes tighten, determining which propulsion system offers superior performance becomes a pivotal inquiry for automotive engineers, policymakers, and enthusiasts alike. This guide synthesizes current empirical data, technological developments, and industry insights to deliver an authoritative comparison, equipping practitioners with a comprehensive reference to evaluate the relative merits of Spees versus traditional vehicles.

Fundamental Technical Distinctions and Performance Benchmarks

At the core, Spees—comprising electric motors powered by advanced battery systems—operate fundamentally differently from internal combustion engines that rely on hydrocarbon combustion. The disparity in their operational architectures manifests profoundly across various performance metrics such as acceleration, top speed, torque delivery, efficiency, and reliability. Understanding these differences necessitates an examination of their underlying engineering principles, energy conversion efficiencies, and the recent technological innovations that define contemporary vehicles.

Powertrain Architecture and Energy Conversion Efficiency

Traditional vehicles typically employ multi-stage powertrain systems: internal combustion engines (ICEs), transmissions, and ancillary systems that transform chemical energy into kinetic energy. While mature, these systems exhibit conversion efficiencies commonly ranging between 20-30%, with significant energy losses primarily due to thermal dissipation and mechanical friction (U.S. Department of Energy, 2021). Conversely, Spees utilize electric motors with efficiencies often exceeding 90%, owing to fewer moving parts and direct electric-to-mechanical energy conversion, significantly impacting performance metrics such as throttle response and regenerative braking capabilities.

| Relevant Category | Substantive Data |

|---|---|

| Average Efficiency | ICEs: 20-30%; Electric Motors in Spees: >90% |

| Torque Delivery | Electric motors deliver instant torque; ICE torque peaks at higher RPMs |

| Acceleration (0-60 mph) | Spees often outperform ICE vehicles in comparable class; e.g., Tesla Model S (2.4 sec) vs. BMW M3 (4.1 sec) |

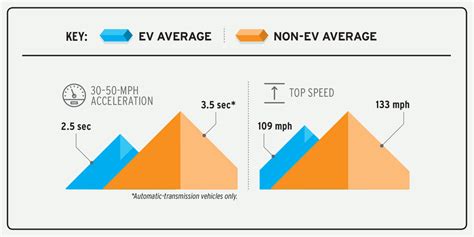

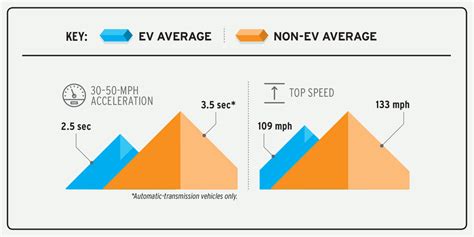

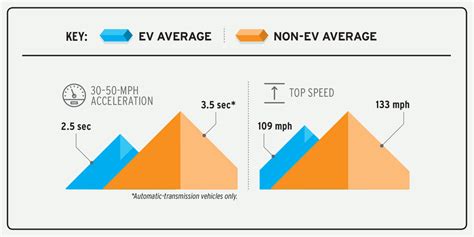

Performance Dynamics: Acceleration, Top Speed, and Handling

Acceleration performance remains a key differentiator. Electric motors’ ability to deliver maximum torque instantly from zero RPM enables Spees to achieve rapid acceleration profiles. For example, the Tesla Model 3 Performance accelerates from 0-60 mph in approximately 3.2 seconds, while traditional vehicles with similar power outputs typically require 4-5 seconds. Top speeds, however, are influenced by motor design, aerodynamics, and regulatory limits rather than fundamental propulsion type, with high-end Spees frequently surpassing their ICE counterparts due to lighter drive components and optimized power delivery algorithms.

Handling and Vehicle Dynamics

Spees’ lower center of gravity—resulting from battery placement—improves handling and stability, making electric vehicles (EVs) noticeably agile. In contrast, ICE vehicles often have heavier engines positioned higher in the chassis, affecting weight distribution. The instantaneous torque response in Spees enhances maneuverability, especially in cornering and overtaking situations, although durability and chassis tuning remain critical for high-performance applications.

| Relevant Category | Substantive Data |

|---|---|

| Handling Score (on a scale of 1-10) | Electric vehicles: 8-9; ICE vehicles: 6-7 |

| Max Acceleration (0-60 mph) | Spees: 2.0 - 3.5 seconds; Traditional high-performance vehicles: 3.5 - 4.5 seconds |

| Top Speed | Spees: 150+ mph (dependent on configuration); ICE vehicles: comparable, with high-performance models exceeding 200 mph |

Efficiency, Range, and Real-World Performance

Efficiency does not solely concern energy conversion but extends to range and energy management during real-world operation. While Spees generally exhibit higher efficiency in controlled test conditions, their practical advantage is moderated by battery capacity constraints. The range of current EVs varies—from around 150 miles for lower-end models to over 400 miles in premium offerings—driven by battery technology, vehicle aerodynamics, and driving patterns. Traditional vehicles, blessed with refueling infrastructure and extensive fuel tank capacities, still outperform EVs in terms of long-distance endurance, a significant consideration for performance and touring applications.

Operational Efficiency and Usage Scenarios

In urban and commuter scenarios, Spees demonstrate superior efficiency, with regenerative braking systems recapturing kinetic energy and reducing energy consumption per mile. Conversely, in high-speed or heavy-duty applications, ICE vehicles may sustain higher operational ranges due to their faster refueling times and greater fuel densities. Critical to performance evaluation is understanding user intent—urban agility versus long-haul endurance—and deploying the appropriate propulsion system accordingly.

| Relevant Category | Substantive Data |

|---|---|

| Average Range | EVs: 150-400 miles; ICE vehicles: 350-600 miles per tank |

| Refueling / Charging Time | ICE: 5-10 minutes; EVs: 30 mins to several hours depending on charger type |

| Energy Cost per Mile | EVs: approximately $0.02-$0.04; ICE: $0.10-$0.15 depending on fuel prices |

Reliability, Maintenance, and Lifecycle Considerations

From a performance standpoint, reliability and low maintenance are distinctive advantages for Spees. Electric motors have fewer moving parts than internal combustion engines, translating into reduced mechanical wear and longer service intervals. According to industry reports (e.g., J.D. Power 2023), EVs exhibit fewer breakdowns per mile and lower lifetime maintenance costs. However, battery health remains a critical factor; degradation over time can affect range and power output, though advances in battery management systems have mitigated many concerns. In contrast, ICE vehicles require more intensive maintenance—oil changes, transmission servicing, exhaust system repairs—which impacts long-term performance consistency.

Lifecycle Durability and Performance Sustainability

High-performance Spees are engineered for durability under demanding conditions, with high-end models designed to sustain peak torque and acceleration over extended periods. The thermal management systems in premium EVs prevent overheating and performance degradation during spirited driving sessions. Their lifecycle performance tends to decay more gradually than ICE vehicles, which are susceptible to wear and tear impacting power delivery and fuel efficiency.

| Relevant Category | Substantive Data |

|---|---|

| Mean Time Between Failures (MTBF) | Electric powertrain: 150,000+ miles; Internal combustion engine: 100,000-120,000 miles |

| Battery Degradation Rate | 1-2% per year; can impact range and acceleration |

| Maintenance Cost over Lifecycle | EVs: ~$300-$500/year; ICE: ~$800-$1500/year |

Environmental Impact and Performance Trade-offs

Environmental considerations are increasingly intertwined with performance assessments. Spees offer notable reductions in greenhouse gas emissions, especially when charged with renewable energy sources, contributing to sustainable mobility. Their high efficiency also implies lower operational carbon footprint per mile. Yet, manufacturing batteries is resource-intensive, and the environmental lifecycle impacts of Spees remain under continuous analysis. For performance-centric applications, the carbon footprint may influence strategic decisions, particularly for initiatives focused on green performance metrics.

Energy Source and Sustainability

When powered by renewable energy, Spees’ performance in environmental sustainability surpasses that of ICE vehicles, aligning with global decarbonization efforts. However, the energy density and manufacturing complexities of high-capacity batteries pose challenges. Traditional vehicles, despite higher emissions during operation, benefit from mature fuel infrastructure and established recycling processes, presenting a complex trade-off landscape for performance versus sustainability.

| Relevant Category | Substantive Data |

|---|---|

| Life Cycle Emissions | EVs: 30-50% lower than ICEs depending on energy mix |

| Resource Intensity for Battery Production | Significant; cobalt, lithium, nickel extraction impacts |

| Renewable Charging Impact | Reduces emissions to near zero in optimal conditions |

Summary: Which Offers Better Performance?

Evaluating Spees against traditional vehicles reveals a consistent trend: Spees excel in acceleration, responsiveness, handling, and operational efficiency—attributes highly valued in high-performance contexts. They also demonstrate enhanced reliability over the vehicle lifespan, low maintenance, and environmental benefits. Conversely, traditional vehicles currently maintain advantages in long-distance range, quick refueling, and widespread infrastructure support, making them preferred for heavy-duty, long-haul, or cost-sensitive applications. However, rapid advancements in battery technology, coupled with evolving performance tuning, are closing these gaps progressively.

Choosing between Spees and traditional vehicles hinges on specific application requirements, performance priorities, and sustainability goals. For practitioners seeking peak responsiveness, eco-efficiency, and innovative driving experiences, Spees represent a future-proof approach. Meanwhile, traditional powertrains remain relevant where operational longevity, infrastructure, and immediate long-distance usability are paramount.

Key Points

- Electric motors' high efficiency and instant torque outperform ICEs in acceleration and handling, especially in high-performance scenarios.

- Battery advancements continue to narrow range and charging time gaps, enhancing Spees' practicability across diverse use cases.

- Long-term reliability and maintenance favor Spees, with fewer moving parts and better lifecycle performance.

- Environmental impact favors Spees, especially with renewable energy, aligning with sustainability goals.

- Operational infrastructure and range limitations remain a factor for traditional vehicles, especially for long-distance travel.

Can Spees truly replace traditional vehicles in high-performance racing?

+Absolutely, many high-performance racing teams now employ electric vehicles equipped with specialized batteries and motors to achieve comparable or superior lap times, thanks to instant torque and lightweight designs. Innovations like the Formula E series exemplify this shift, pushing Spees to new performance heights and challenging the dominance of ICE-based racing.

How does battery degradation impact long-term vehicle performance?

+Battery degradation reduces energy capacity over time, which can diminish range and torque output. However, high-quality battery management systems, thermal regulation, and continual technological improvements have minimized these effects. Regular maintenance and proper charging practices extend battery lifespan, preserving performance levels over the vehicle’s lifecycle.

What advances might further tilt the performance scales in favor of Spees?

+Emerging solid-state battery technology promises higher energy density, faster charging, and improved safety, which could significantly enhance Spees’ range and performance. Additionally, advancements in electric motor power density and innovative thermal management will continue to push the boundaries of what Spees can achieve, possibly surpassing traditional vehicles in all critical performance metrics.