SpaceX has confirmed that the two large propellant tanks now present at its Boca Chica, Texas facilities will likely to be the last major ground tanks needed to enable the first test flights of the upper stage of its next-gen BFR rocket, known as the Big Falcon Spaceship (BFS).

Expected to begin as soon as late 2019, SpaceX executives have recently reiterated plans for a campaign of hop tests for the first full-scale spaceship prototype, in which the ship will follow in the footsteps of its Falcon 9-based Grasshopper and F9R predecessors.

https://twitter.com/krgv_mike/status/1055748966619537408

In a comment provided to a number of local outlets, SpaceX Communications Specialist Sean Pitt stated this about the recent arrival of a second large propellant storage tank at the company’s prospective South Texas test and launch facilities.

“The ongoing construction of our launch pad in South Texas is proceeding well. SpaceX has now received the final major ground system tank needed to support initial test flights of the Big Falcon Spaceship.” – Sean Pitt, SpaceX

While there may have been some slight uncertainty before, this official statement confirms beyond the shadow of a doubt that SpaceX is actively and rapidly preparing its South Texas property for a future of BFR-related tests, spaceship hops, and perhaps even launches.

Same dance, different hops

Unlike Falcon 9’s Grasshopper and F9R reusability development programs, SpaceX’s BFS hop test campaign is likely going to be much more aggressive in order to gather real flight-test data on new technologies ranging from unfamiliar aerodynamic control surfaces (wings & fins vs. grid fins), all-composite propellant tanks (Falcon uses aluminum-lithium), a 9m-diameter vehicle versus Falcon’s 3.7m, a massive tiled heat-shield likely to require new forms of thermal protection, and entirely new regimes of flight (falling like a skydiver rather than Falcon 9’s javelin-style attitude) – to name just a handful.

To fully prove out or at least demonstrate those new technologies, BFS hop testing is likely to be better described as “flight testing”, whereby the spaceship launches vertically but focused primarily on regimes where horizontal velocity is far more important than vertical velocity.

“But by ‘hopper test,’ I mean it’ll go up several miles and then come down. The ship will – the ship is capable of a single stage to orbit if you fully load the tanks. So we’ll do flights of increasing complexity. We really want to test the heat shield material. So I think we’ll fly out, turn around, accelerate back real hard and come in hot to test the heat shield because we want to have a highly reusable heat shield that’s capable of absorbing the heat from interplanetary entry velocities, which is really tricky.” – CEO Elon Musk, October 2017

Focusing on the important things (for fully-reusable rockets)

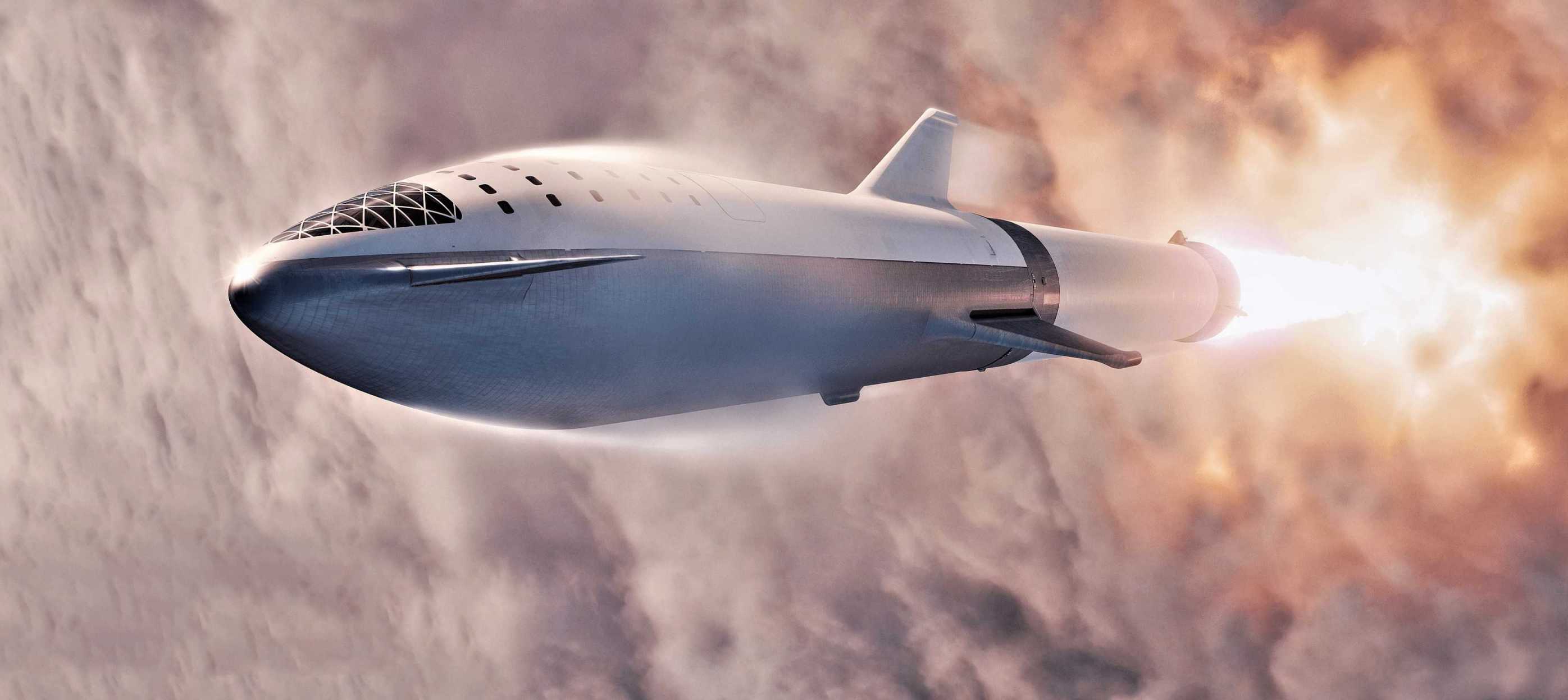

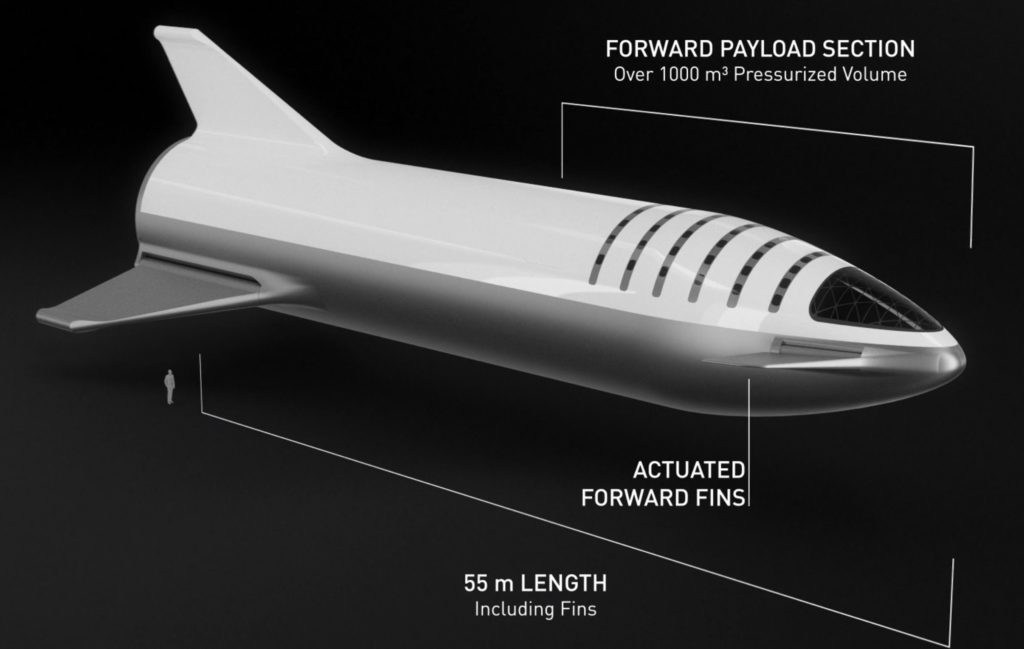

SpaceX does has significant familiarity with the general style of testing expected to be used to prove out its next-gen spaceship, a major department from anything the company has yet built or flown. Updated in September 2018 by CEO Elon Musk, the craft’s most recent design iteration is reportedly quite close to being finalized. That near-final design prominently features a trio of new aft fins (two able to actuate as control surfaces), two forward canards, and an updated layout of seven Raptor engines.

Critically, SpaceX has decided to commonize BFR’s main propulsion, choosing to skip the performance benefits of a vacuum-optimized Raptor variant for the simplicity and expediency of exclusively using sea level Raptors on both the booster and spaceship. This decision is ultimately strategic and well-placed: rather than concerning early-stage development with the inclusion of a second major branch of onboard propulsion, the company’s engineers and technicians can place their focus almost entirely on a one-size-fits-all version of BFR with plenty of room for upgrades down the road.

- BFS seen standing vertically on the pads of its tripod fins. (SpaceX)

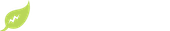

- (SpaceX)

- A better view. (SpaceX)

- BFR’s booster and spaceship separate a few minutes after launch. (SpaceX)

With a rocket as large as BFR and a sea level engine already as efficient as Raptor, the performance downgrade wrought by the initial removal of Raptor Vacuum (RVac) is scarcely more than a theoretical diversion. The specific performance numbers remain to be seen but will likely be greater than 100 metric tons (~220,000 lbs) to low Earth orbit (LEO). Past a certain point, however, the actual performance to LEO and beyond is almost irrelevant, at least from a perspective of individual launches. The paradigm SpaceX is clearly already interrogating is one where the cost of individual launches is so low relative to today’s expendable launch pricing ($5,000-20,000/kg to LEO) that it will almost be anachronistic to design or work with a single-launch-limit in mind, a limit that is just shy of a natural law in the spaceflight industries of today.

Because SpaceX has already demonstrated expertise in vertically launching, landing, and generally controlling large rockets, the main challenges faced with BFR are more operational than purely technical. To be clear, the technical challenges are still immense, but successfully solving those challenges by no means guarantees that the aircraft-like operational efficiency needed for BFR to succeed can or will be fully realized.

- A gif of Raptor throttling over the course of a 90+ second static-fire test in McGregor, Texas. (SpaceX)

- SpaceX’s subscale Raptor engine has completed more than 1200 seconds of testing in less than two years. (SpaceX)

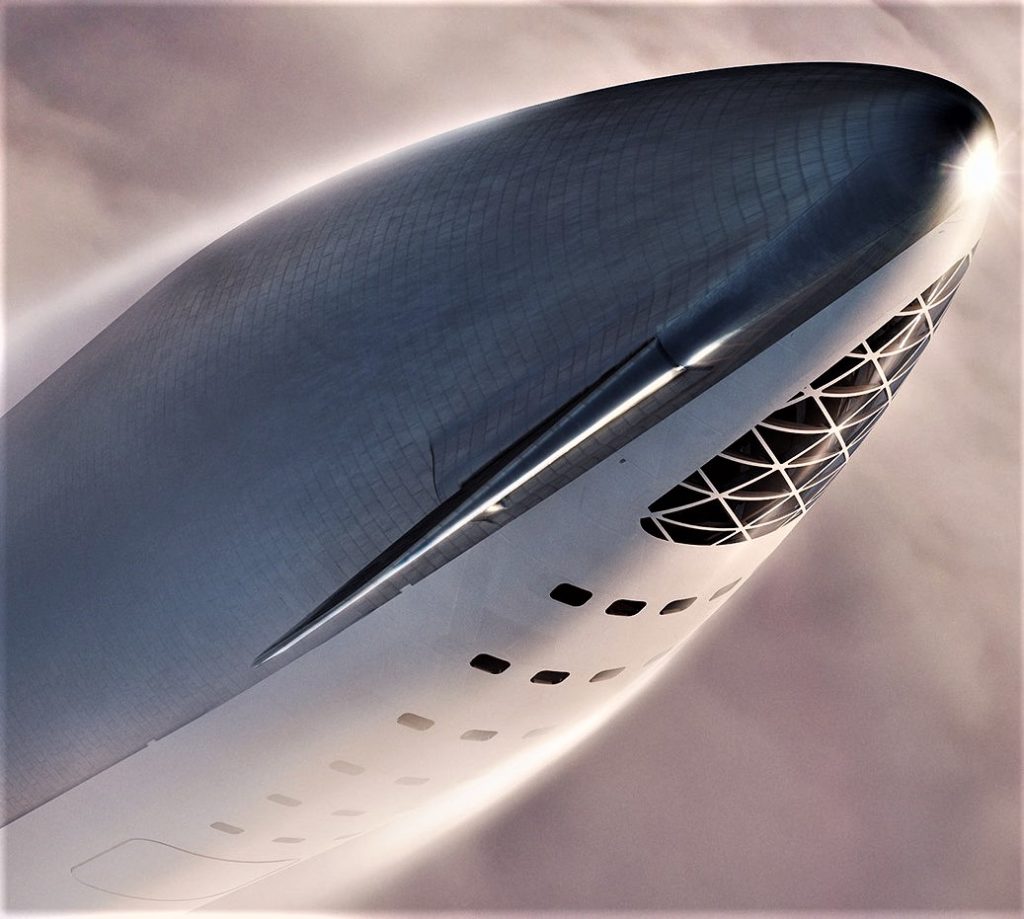

- A closeup of BFS’ nose section, featuring impressively varied tile-sizes, joining methods, and extremely precise curves on the interface between canard wings and the hull. (SpaceX)

In 2016, Musk pegged SpaceX’s cost goals for a BFR-style fully-reusable rocket at less than $1M per launch for booster and spaceship maintenance alone, or $3.3M per launch with amortization (paying for the debt/investment incurred to fund BFR’s development) and propellant estimates included. To realize those ambitious costs, SpaceX will effectively have to beat the expendable but similarly-sized Saturn V’s per-launch costs (~$700M) by a factor of 100 to 200 – more than two orders of magnitude – and SpaceX’s own Falcon 9 and Heavy launch costs (~$55M to $130M) by 20-50X.

To even approach those targets, SpaceX will need to learn how to launch Falcon and BFR near-autonomously with near-total and refurbishment-free reusability, while also developing and demonstrating orbital refueling capabilities that do not currently exist and rapidly maturing large-scale composite tankage and structures. None of those things require Raptor Vacuum.

For prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket recovery fleet check out our brand new LaunchPad and LandingZone newsletters!

News

Armored Tesla Cybertruck “War Machine” debuts at Defense Expo 2025

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Temporibus autem quibusdam et aut officiis debitis aut rerum necessitatibus saepe eveniet ut et voluptates repudiandae sint et molestiae non recusandae. Itaque earum rerum hic tenetur a sapiente delectus, ut aut reiciendis voluptatibus maiores alias consequatur aut perferendis doloribus asperiores repellat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

“Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat”

Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt.

Et harum quidem rerum facilis est et expedita distinctio. Nam libero tempore, cum soluta nobis est eligendi optio cumque nihil impedit quo minus id quod maxime placeat facere possimus, omnis voluptas assumenda est, omnis dolor repellendus.

Nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.

Neque porro quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur, adipisci velit, sed quia non numquam eius modi tempora incidunt ut labore et dolore magnam aliquam quaerat voluptatem. Ut enim ad minima veniam, quis nostrum exercitationem ullam corporis suscipit laboriosam, nisi ut aliquid ex ea commodi consequatur.

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas molestias excepturi sint occaecati cupiditate non provident, similique sunt in culpa qui officia deserunt mollitia animi, id est laborum et dolorum fuga.

Quis autem vel eum iure reprehenderit qui in ea voluptate velit esse quam nihil molestiae consequatur, vel illum qui dolorem eum fugiat quo voluptas nulla pariatur.

News

Tesla Megapacks chosen for 548 MWh energy storage project in Japan

Tesla plans to supply over 100 Megapack units to support a large stationary storage project in Japan, making it one of the country’s largest energy storage facilities.

Tesla’s Megapack grid-scale batteries have been selected to back an energy storage project in Japan, coming as the latest of the company’s continued deployment of the hardware.

As detailed in a report from Nikkei this week, Tesla plans to supply 142 Megapack units to support a 548 MWh storage project in Japan, set to become one of the country’s largest energy storage facilities. The project is being overseen by financial firm Orix, and it will be located at a facility Maibara in central Japan’s Shiga prefecture, and it aims to come online in early 2027.

The deal is just the latest of several Megapack deployments over the past few years, as the company continues to ramp production of the units. Tesla currently produces the Megapack at a facility in Lathrop, California, though the company also recently completed construction on its second so-called “Megafactory” in Shanghai China and is expected to begin production in the coming weeks.

READ MORE ON TESLA MEGAPACKS: Tesla Megapacks help power battery supplier Panasonic’s Kyoto test site

Tesla’s production of the Megapack has been ramping up at the Lathrop facility since initially opening in 2022, and both this site and the Shanghai Megafactory are aiming to eventually reach a volume production of 10,000 Megapack units per year. The company surpassed its 10,000th Megapack unit produced at Lathrop in November.

During Tesla’s Q4 earnings call last week, CEO Elon Musk also said that the company is looking to construct a third Megafactory, though he did not disclose where.

Last year, Tesla Energy also had record deployments of its Megapack and Powerwall home batteries with a total of 31.4 GWh of energy products deployed for a 114-percent increase from 2023.

Other recently deployed or announced Megapack projects include a massive 600 MW/1,600 MWh facility in Melbourne, a 75 MW/300 MWh energy storage site in Belgium, and a 228 MW/912 MWh storage project in Chile, along with many others still.

What are your thoughts? Let me know at zach@teslarati.com, find me on X at @zacharyvisconti, or send us tips at tips@teslarati.com.

Tesla highlights the Megapack site replacing Hawaii’s last coal plant

Need accessories for your Tesla? Check out the Teslarati Marketplace:

News

Elon Musk responds to Ontario canceling $100M Starlink deal amid tariff drama

Ontario Premier Doug Ford said, opens new tab on February 3 that he was “ripping up” his province’s CA$100 million agreement with Starlink in response to the U.S. imposing tariffs on Canadian goods.

Elon Musk company SpaceX is set to lose a $100 million deal with the Canadian province of Ontario following a response to the Trump administration’s decision to apply 25 percent tariffs to the country.

Starlink, a satellite-based internet service launched by the Musk entity SpaceX, will lose a $100 million deal it had with Ontario, Premier Doug Ford announced today.

Starting today and until U.S. tariffs are removed, Ontario is banning American companies from provincial contracts.

Every year, the Ontario government and its agencies spend $30 billion on procurement, alongside our $200 billion plan to build Ontario. U.S.-based businesses will…

— Doug Ford (@fordnation) February 3, 2025

Ford said on X today that Ontario is banning American companies from provincial contracts:

“We’ll be ripping up the province’s contract with Starlink. Ontario won’t do business with people hellbent on destroying our economy. Canada didn’t start this fight with the U.S., but you better believe we’re ready to win it.”

It is a blow to the citizens of the province more than anything, as the Starlink internet constellation has provided people in rural areas across the globe stable and reliable access for several years.

Musk responded in simple terms, stating, “Oh well.”

Oh well https://t.co/1jpMu55T6s

— Elon Musk (@elonmusk) February 3, 2025

It seems Musk is less than enthused about the fact that Starlink is being eliminated from the province, but it does not seem like all that big of a blow either.

As previously mentioned, this impacts citizens more than Starlink itself, which has established itself as a main player in reliable internet access. Starlink has signed several contracts with various airlines and maritime companies.

It is also expanding to new territories across the globe on an almost daily basis.

With Mexico already working to avoid the tariff situation with the United States, it will be interesting to see if Canada does the same.

The two have shared a pleasant relationship, but President Trump is putting his foot down in terms of what comes across the border, which could impact Americans in the short term.