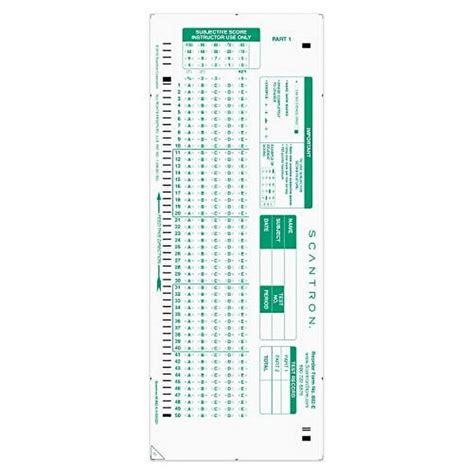

In the realm of educational assessments and standardized testing, the Scantron machine has long served as a pivotal tool for efficiently grading large volumes of multiple-choice exams. Its roots trace back to the mid-20th century, revolutionizing how tests are scored by converting handwritten responses into machine-readable data. Despite the advent of digital assessment platforms, the Scantron remains prevalent in many testing environments due to its speed, reliability, and cost-effectiveness. Yet, while the technology appears straightforward—bubble in, feed, process—the optimal utilization of a Scantron machine requires an understanding of its nuances, limitations, and best practices. Decoding the intricacies of its operation, therefore, becomes essential for educators, administrators, and testing professionals who seek accuracy and efficiency in assessment processes. This article compares traditional manual grading approaches with electronic scanning via Scantron, illustrates technical enhancements for maximizing accuracy, and explores future trends in assessment technology.

Understanding the Fundamentals of Scantron Technology versus Manual Grading

The core of the debate centers around the comparison between manual grading of answer sheets—a labor-intensive process prone to human error—and the automation offered by Scantron systems. Manual grading involves educators or administrative staff physically reviewing and marking answer sheets, a task that becomes increasingly cumbersome with large class sizes or standardized testing suites. Although perceived as inherently subjective and inherently slow, manual methods can allow nuanced understanding of student handwriting or contextual clues, but often at the expense of accuracy and efficiency.

Conversely, Scantron machines utilize optical mark recognition (OMR) technology to rapidly scan and interpret answer bubbles. These systems have advanced significantly since their inception, integrating robust image processing algorithms, enhanced calibration, and error detection features. Importantly, the transition from manual to machine-based grading reduces human error, improves throughput, and standardizes scoring, fostering fairness and consistency across evaluations.

Comparative Analysis of Accuracy, Cost, and Operational Speed

| Aspect | Manual Grading | Scantron Machine |

|---|---|---|

| Accuracy | Highly dependent on grader vigilance; susceptible to fatigue-induced errors (3-5% error rate) | High precision (up to 99%) when properly calibrated; influenced by answer sheet quality |

| Cost | Labor costs and time-intensive; suitable for small-scale assessments | Initial investment needed (10,000–50,000); low per-test cost thereafter |

| Speed | Seconds per sheet, but accumulative delays for large volumes | Processing thousands of sheets within minutes |

Technical Aspects of Using a Scantron Machine Effectively

Maximizing the efficiency and accuracy of scantron-based assessment hinges on understanding the technical parameters and minimizing common pitfalls. Optical mark recognition relies heavily on the quality of answer sheets, demographic data, and correct configuration of the machine’s calibration settings. The primary considerations include paper quality, marking style, and answer sheet design.

Optimizing Paper Quality and Marking Strategies

Implementing high-contrast, smudge-free bubbles on answer sheets ensures the optical sensors correctly detect responses. Educators are advised to instruct students to fill bubbles completely with dark, consistent marks—preferably using #2 pencils or compatible pens, depending on machine specifications. Maintaining answer sheet integrity by avoiding folds, tears, or extraneous marks is equally critical, as imperfections can lead to misreads or rejection.

| Parameter | Recommended Practice |

|---|---|

| Answer markings | Dark, full bubbles; avoid partial fills or scribbles |

| Sheet handling | Store in a flat, dry environment; use clean, smooth sheets |

| Calibration | Perform calibration tests weekly or when changing batchs to ensure accuracy |

Limitations and Potential Errors in Scantron Usage

Despite its technological advancements, the Scantron system is not infallible. Certain limitations include sensitivity to answer sheet quality, potential misreads due to ambiguous markings, and issues with answer sheet handling that can lead to skewed data or processing errors. For instance, answer sheets with faint bubbles or overlapping marks can cause incorrect scoring or rejection. Additionally, environmental factors such as static electricity or improper machine maintenance can introduce errors.

Common Troubleshooting and Error Prevention

Regularly inspecting equipment for dirt, dust, or mechanical wear, alongside routine updates of the software firmware, can mitigate many issues. Staff training on proper answer sheet handling, including aligning sheets correctly in the feeder and avoiding obstructive marks, enhances system reliability. When discrepancies occur, reviewing scanned images manually can help identify patterns of errors—whether related to answer marking styles, answer sheet quality, or machine calibration—and inform corrective actions.

| Error Type | Potential Cause |

|---|---|

| False negatives | Faint or incomplete bubble filling |

| Misreads | Overlapping marks or extraneous annotations |

| Rejection | Poor paper quality or improper feeding |

Future Trends in Assessment Technology: Beyond Traditional Scantron

The landscape of assessment technology is inching toward smarter, more integrated solutions. Portable digital scanning devices, AI-powered image recognition, and cloud-based data management are increasingly replacing conventional paper-based systems. These innovations aim to address current limitations, such as manual data entry errors, limited customization, and environmental concerns regarding paper waste.

Emerging Technologies and Their Comparative Advantages

Digital assessment platforms leverage machine learning algorithms to interpret responses from both paper and digital sources, offering real-time analytics and adaptive testing features. These systems often integrate biometric authentication, secure data storage, and seamless integration with learning management systems. In comparison, traditional Scantron systems, while robust, lack such flexibility and real-time adaptability.

| Innovation | Advantages |

|---|---|

| AI-enhanced OCR | Higher accuracy, ability to interpret ambiguous marks, and adaptive scoring |

| Cloud-based systems | Instant access, scalable data analysis, and integration with educational analytics |

| Digital testing tools | Interactive assessments, multimedia integration, and immediate feedback |

Final Reflections: Deciphering the Optimal Use of Scantron in Modern Education

In sum, the effective utilization of Scantron machines hinges on mastering the interplay between technical precision, strategic application, and ongoing system management. While newer digital alternatives promise a paradigm shift in assessment, Scantron remains a stalwart in contexts where simplicity, reliability, and cost-efficiency are paramount. For educators and administrators, understanding the detailed mechanics, limitations, and best practices associated with Scantron systems isn’t merely a technical skill but a strategic imperative—ensuring that every evaluation offers valid, reliable, and timely results that support educational outcomes.

What are the key advantages of using a Scantron machine over manual grading?

+Scantron machines provide rapid, accurate grading for large volumes of exams, reduce human error, and ensure consistent scoring, making them ideal for large-scale standardized assessments.

How can I improve the accuracy of Scantron-based assessments?

+Ensure answer sheets are of high quality, instruct students on correct marking techniques, perform regular calibration of the scanner, and conduct post-scanning audits to catch errors early.

What emerging technologies are likely to influence future assessment methods?

+AI-powered optical recognition, cloud-based scoring platforms, biometric authentication, and integrated multimedia assessments are shaping the next generation of evaluation tools, offering greater speed, accuracy, and flexibility.