When examining the evolution of respiratory protection, few developments have impacted occupational health as profoundly as the N95 respirator and its accompanying fit testing procedures. Originating from a backdrop of growing awareness about airborne hazards, particularly in industrial and healthcare environments, the N95 mask emerged as a standard bearer for filtering efficiency. However, the realization that a mask’s filtration capacity is only as effective as its fit has led to rigorous testing protocols—collectively known as the N95 fit test—that ensure users derive maximum protective benefit. The transition from basic mask wearing to adopting scientifically validated fit testing reflects both technological advancement and a nuanced understanding of respiratory protection. This article explores the origins, evolution, and contemporary significance of the N95 fit test, presenting a foundational guide to understanding its purpose, process, and implications for workplace safety.

The Origins and Evolution of Respiratory Protective Devices

The story of respiratory protection devices begins in the early 20th century, with the advent of industrialization bringing new occupational hazards involving dust, fumes, and microbial agents. Initial efforts focused largely on dust masks, typically designed with simple cloth or gauze media, which offered limited filtration and rely heavily on facial fit. These early designs underscored a fundamental limitation: even high-efficiency filter media could be rendered ineffective if gaps existed between the mask and the wearer’s face. This understanding prompted pioneering efforts in the mid-20th century to standardize respiratory protection, culminating in the development of more sophisticated devices capable of filtering airborne particles with high efficiency, parametrized by their particulate matter (PM) filtration rating.

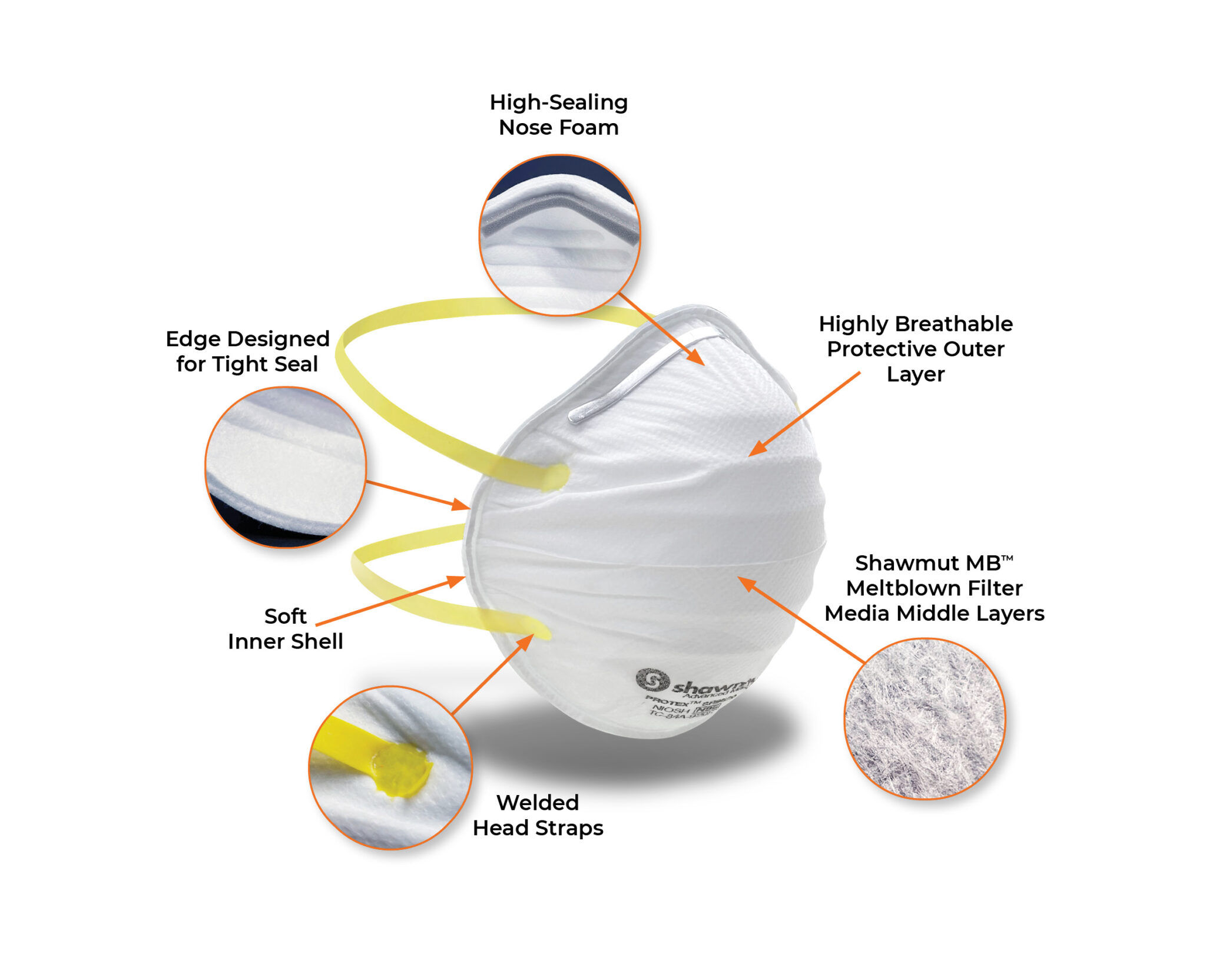

Among these, the N95 class of respirators, designated by the U.S. National Institute for Occupational Safety and Health (NIOSH) in 1995, represents a significant milestone. The “N95” label indicates that the mask filters at least 95% of airborne particles 0.3 micrometers in diameter— an industry standard borne out of rigorous testing protocols. What set N95 masks apart was not only their filtration efficiency but also the recognition that a respirator’s real-world performance depends heavily on proper fit. This insight has persisted, emphasizing that proper fit is as critical as the filter media itself in ensuring respiratory protection.

The Scientific Basis for Fit Testing

The realization that occupational protection depends on effective sealing led to dedicated research on fit testing. Early experiments, dating to the 1960s, were designed to quantify the leakage of airborne particles into the mask during typical movements and speech. These foundational studies demonstrated a clear correlation between mask fit and filtration performance, prompting regulatory bodies worldwide to adopt fit testing as an integral part of respiratory protection programs. In essence, a perfect filter media cannot compensate for poor facial seal; thus, ensuring a proper fit through testing became a health and safety imperative.

Modern engineering of fit testing involves quantifying the inward leakage of test agents—commonly aerosolized particles or generated gases—and establishing protocols to assess fit accuracy. These methods are combined with ergonomic considerations, recognizing variability in facial features across different populations. The comprehensive approach ensures that respirators are tailored to individual faces to the extent possible, reducing the risk of unfiltered air bypassing the mask’s filtration media. As science advanced, standardized fit testing procedures emerged, formalized into regulatory guidelines around the world, such as OSHA’s 29 CFR 1910.134 in the United States.

How the N95 Fit Test Works: Procedural Overview

Key Components of the Fit Test Procedure

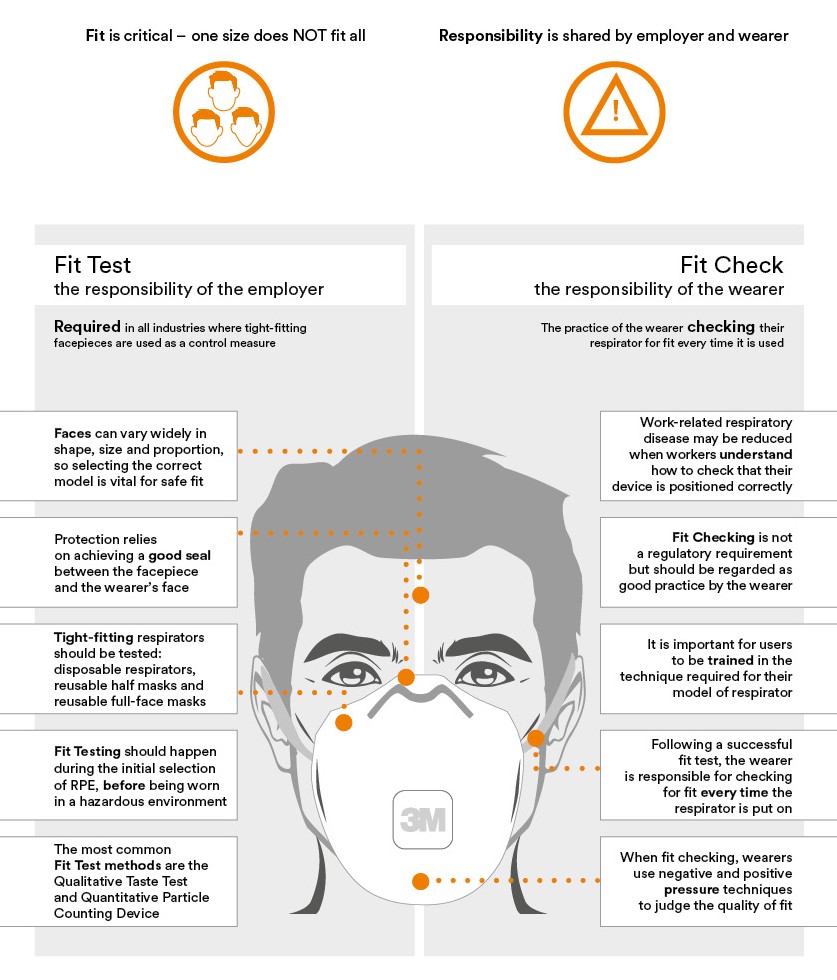

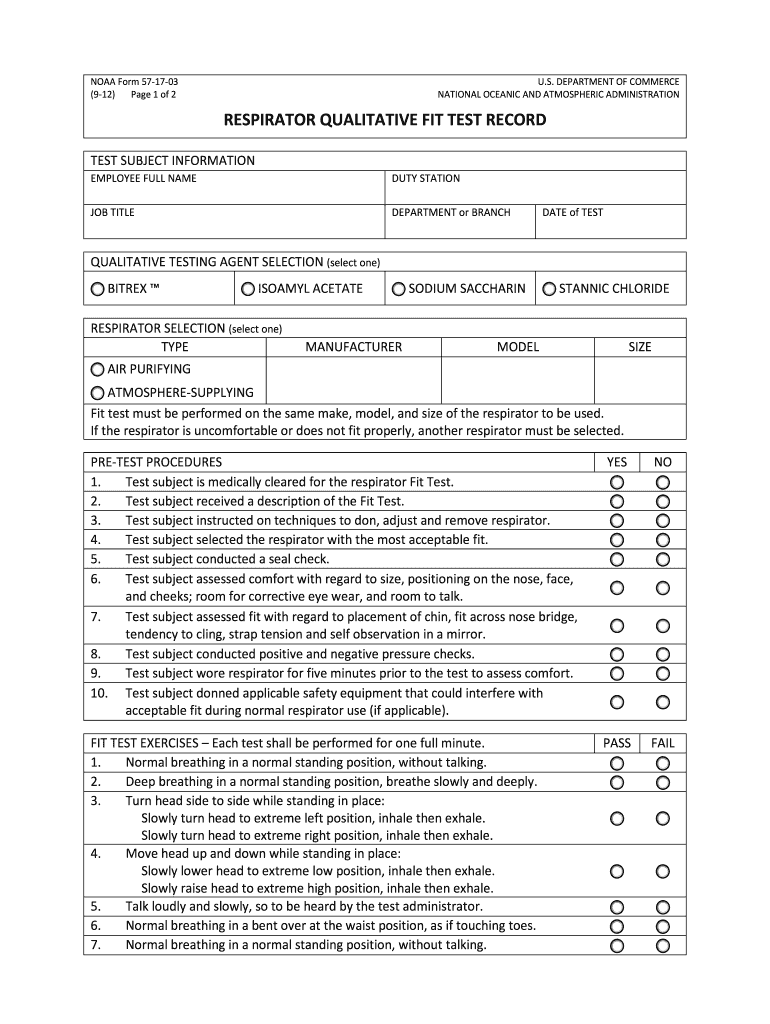

The core objective of the N95 fit test is to verify that the wearer’s facial seal complies with regulatory standards, typically allowing no more than 10% inward leakage during various movements. The process involves exposing the wearer to a controlled test agent while performing common activities, including talking, turning the head, and bending over. The most widely used methods are qualitative and quantitative fit testing, each with distinct advantages—qualitative tests rely on sensory detection of test agents, while quantitative tests use precise instrumentation.

The qualitative fit test (QLFT) often employs taste, smell, or irritation to detect leaks—using agents such as saccharin or Bitrex—making it accessible and straightforward. Conversely, the quantitative fit test (QNFT) utilizes devices like ambient aerosol photometers or condensation particle counters to measure particle counts inside and outside the mask, delivering a numeric fit factor. For N95 masks used in high-risk environments, quantitative testing is often preferred due to its objectivity and precision.

The test begins with a fit check, followed by donning the respirator correctly. The technician then initiates the test, instructing the wearer to perform standard movements as the instrumentation measures inward leakage. Successful passing signifies that the mask maintains a protective seal during movements, providing evidence that the respirator performs as intended.

| Relevant Category | Substantive Data |

|---|---|

| Qualitative Fit Test Agents | Saccharin, Bitrex, irritant smoke; sensitivity test required |

| Quantitative Fit Test Devices | PortaCount, TSI 8038; fit factor ≥ 100 for N95 masks |

| Acceptance Criteria | Fit factor ≥ 100; leakage ≤ 1% during testing |

Implications for Workplace Safety and Regulatory Standards

The integration of fit testing within occupational health frameworks underscores a paradigm shift from passive PPE usage to active verification of protective efficacy. Regulatory agencies such as OSHA, NIOSH, and international counterparts mandate regular fit testing as part of comprehensive respiratory protection programs—especially in sectors like healthcare, industrial manufacturing, and emergency response. This protocol not only ensures compliance but also fosters a culture of safety and accountability.

The importance of proper fit testing was dramatically highlighted during global health crises, such as the COVID-19 pandemic, where surges in demand for PPE strained supply chains and exposed vulnerabilities in protection strategies. Situational analyses demonstrate that institutions with established fit testing procedures experienced lower infection rates among frontline personnel. This emphasizes that beyond acquiring masks, verifying fit enhances overall health resilience in complex work environments.

Technological advances, including portable fit testing units and digital tracking systems, streamline regular testing—enabling organizations to maintain compliance with minimal disruption. Importantly, fit testing also adapts to emerging design innovations, including powered air-purifying respirators (PAPRs), which feature different fitting protocols yet adhere to similar validation principles.

Future Trends and Innovations in N95 Fit Testing

As occupational health paradigms evolve, research is increasingly directed at automating and personalizing fit testing procedures. Emerging solutions include 3D facial imaging, which allows for tailored mask design and individualized fit assessment without the need for traditional fit test agents. Machine learning algorithms process vast facial morphology data to optimize mask shapes, ultimately enhancing comfort and protection.

Moreover, real-time fit monitoring devices—integrated into mask systems—are under development, aiming to provide instant feedback on fit adequacy during daily use. Such innovations promise not only to improve safety but also to reduce the logistical burden associated with periodic retesting.

Ultimately, these advancements will likely lead to hyper-personalized respirator fitting, concurrent with smart PPE technology, ensuring that worker safety keeps pace with technological progress.

Summary and Practical Recommendations

Understanding the N95 fit test entails appreciating its historical context, scientific underpinnings, and role in occupational health. For newcomers, grasping the procedural nuances and regulatory frameworks can seem daunting, but with solid foundational knowledge, stakeholders can implement effective respiratory protection programs. Regular fit testing remains the cornerstone of these efforts, directly correlating with actual on-the-field safety and health outcomes.

Organizations seeking to optimize their respiratory protection should integrate routine fit testing, leverage emerging technologies for better fit predictability, and foster a culture attentive to facial changes over time. Healthcare workers, industrial employees, and emergency responders alike benefit from these measures, which transform passive PPE into active, verified safety guarantees.

Key Points

- Historical evolution highlights that fit testing is vital for maximizing N95 respirator efficiency.

- Qualitative and quantitative methods offer complementary approaches for verifying fit accuracy.

- Regulatory standards insist on periodic re-testing, especially with changes in facial features or mask design.

- Advanced technologies like 3D imaging and real-time monitoring enhance fit assessment capabilities.

- Implementing thorough fit testing strategies directly correlates with improved occupational safety outcomes.

What is the primary purpose of an N95 fit test?

+The primary purpose is to confirm that the respirator forms an adequate seal on the wearer’s face, preventing unfiltered air from bypassing the filter media and ensuring optimal protection during occupational tasks.

How often should fit testing be conducted for N95 masks?

+Guidelines typically recommend annual fit testing, or more frequently if the wearer’s facial features change due to weight fluctuations, facial hair growth, or other factors that may affect mask fit.

Can a person with facial hair pass an N95 fit test?

+Generally, facial hair such as beards and stubble can interfere with the seal, making it unlikely to pass standard fit tests. Regulations often specify that a clean-shaven face is necessary for proper fit and protection.

Are there differences between qualitative and quantitative fit testing methods?

+Yes, qualitative tests rely on sensor detection of taste or smell, providing subjective results, while quantitative tests utilize precise measurement devices to produce an objective fit factor score, offering higher accuracy and reproducibility.

What advances are currently shaping the future of fit testing?

+Innovations such as 3D facial imaging, personalized mask design, and real-time fit monitoring are emerging, working toward more precise, user-specific, and efficient fit validation in occupational settings.