When it comes to the electrical systems of a car, the harness is a critical component that ensures all electrical components are connected and functioning properly. The electrical harness, also known as the wiring harness, is a complex system of wires, connectors, and other components that distribute electrical power throughout the vehicle. In this article, we will provide 5 tips for working with electrical harnesses in cars, highlighting the importance of proper installation, maintenance, and repair.

Understanding the Electrical Harness

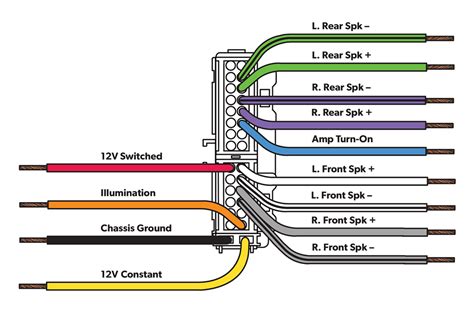

The electrical harness is a custom-designed system for each vehicle, taking into account the specific electrical requirements of the car’s components. It includes wires of various gauges, colors, and insulation types, all carefully routed and secured to ensure reliable operation. A well-designed and properly installed electrical harness is essential for the safe and efficient operation of a vehicle’s electrical systems.

Tip 1: Use High-Quality Materials

When working with electrical harnesses, it is crucial to use high-quality materials that meet or exceed the original equipment manufacturer (OEM) specifications. This includes wires, connectors, and other components that are designed to withstand the harsh conditions found in a vehicle’s electrical system. Using substandard materials can lead to premature failure, electrical fires, or other safety hazards.

| Material | Specification |

|---|---|

| Wire Gauge | AWG (American Wire Gauge) 18-22 for most applications |

| Insulation Type | PVC (Polyvinyl Chloride) or Teflon for high-temperature applications |

| Connector Type | Weather-sealed connectors with gold-plated contacts |

Design and Installation Considerations

A proper electrical harness design takes into account the specific requirements of the vehicle’s electrical systems, including the type and number of components, wire routing, and connector placement. The installation process requires careful planning and execution to ensure that all components are securely connected and the harness is properly routed and secured.

Tip 2: Follow Proper Installation Procedures

When installing an electrical harness, it is essential to follow proper procedures to ensure a safe and reliable connection. This includes using the correct tools and techniques for wire stripping, crimping, and soldering, as well as properly securing the harness to the vehicle’s chassis and components.

Some key considerations when installing an electrical harness include:

- Ensuring all connections are secure and meet the OEM's torque specifications

- Using wire ties and cable clamps to secure the harness to the vehicle's chassis and components

- Avoiding wire chafing and abrasion by routing the harness away from moving parts and sharp edges

- Testing the electrical system thoroughly after installation to ensure proper function and identify any potential issues

Troubleshooting and Repair

Despite proper design and installation, electrical harnesses can still fail or develop issues over time. Common problems include wire damage, connector corrosion, and faulty components. When troubleshooting an electrical harness, it is essential to use a systematic approach to identify the root cause of the problem and make the necessary repairs.

Tip 3: Use a Systematic Approach to Troubleshooting

A systematic approach to troubleshooting an electrical harness involves using a combination of visual inspection, electrical testing, and diagnostic tools to identify the source of the problem. This may include:

- Visually inspecting the harness for signs of damage, wear, or corrosion

- Using a multimeter to test voltage, current, and resistance in the electrical system

- Employing diagnostic tools, such as scan tools and circuit testers, to identify faults and pinpoint the source of the problem

Key Points

- Use high-quality materials that meet or exceed OEM specifications

- Follow proper installation procedures to ensure a safe and reliable connection

- Use a systematic approach to troubleshooting electrical harness issues

- Regularly inspect and maintain the electrical harness to prevent issues and ensure reliable operation

- Consider seeking the help of a professional automotive electrician for complex electrical harness repairs

Maintenance and Inspection

Regular maintenance and inspection of the electrical harness are essential to prevent issues and ensure reliable operation. This includes visually inspecting the harness for signs of damage or wear, testing the electrical system, and performing routine repairs and replacements as needed.

Tip 4: Regularly Inspect and Maintain the Electrical Harness

Regular inspection and maintenance of the electrical harness can help prevent issues and ensure reliable operation. This includes:

- Visually inspecting the harness for signs of damage, wear, or corrosion

- Testing the electrical system to ensure proper function and identify any potential issues

- Performing routine repairs and replacements as needed, such as replacing worn or damaged wires and connectors

Tip 5: Consider Seeking Professional Help

While some electrical harness repairs can be performed by a DIY enthusiast, more complex issues may require the help of a professional automotive electrician. A professional can provide the necessary expertise and equipment to diagnose and repair complex electrical harness issues, ensuring a safe and reliable repair.

What are the common causes of electrical harness failure?

+Common causes of electrical harness failure include wire damage, connector corrosion, and faulty components. Regular inspection and maintenance can help prevent these issues and ensure reliable operation.

How often should I inspect and maintain my electrical harness?

+Regular inspection and maintenance of the electrical harness are essential to prevent issues and ensure reliable operation. It is recommended to inspect the harness at least once a year, or more frequently if you notice any signs of damage or wear.

Can I repair my electrical harness myself, or should I seek professional help?

+While some electrical harness repairs can be performed by a DIY enthusiast, more complex issues may require the help of a professional automotive electrician. If you are unsure about your ability to repair the harness, it is recommended to seek professional help to ensure a safe and reliable repair.

Meta Description: Learn 5 essential tips for working with electrical harnesses in cars, including using high-quality materials, following proper installation procedures, and regularly inspecting and maintaining the harness.