In the evolving landscape of energy storage and power delivery, two competing paradigms have emerged as focal points: carbon electric charge systems and traditional battery power. Both approaches carry distinct philosophies, technological complexities, and practical implications that influence sectors ranging from consumer electronics and electric vehicles to large-scale grid management. Exploring their comparative landscapes provides clarity on their respective advantages and limitations, thus informing stakeholders about the trajectory of future energy solutions.

Understanding the Fundamentals: Carbon Electric Charge and Traditional Batteries

At the core, traditional batteries—such as lithium-ion and lead-acid variants—depend on electrochemical processes to store and release electrical energy. Their operational principle involves reversible chemical reactions within electrodes, with ion transfer facilitating charge flow. This technology has become ubiquitous due to its proven reliability, high energy density, and mature manufacturing ecosystem.

Conversely, the concept of carbon electric charge harnesses the vast potential of carbon-based materials—particularly forms like graphene, carbon nanotubes, and activated carbon—to facilitate energy storage and transfer. While not a single, discrete technology akin to batteries, carbon-based systems often refer to methods such as supercapacitors or capacitive energy storage, where electrical charge is stored physically rather than chemically. These systems leverage the high surface area and conductivity of carbon allotropes to enable rapid charge and discharge cycles, potentially revolutionizing energy delivery paradigms.

| Relevant Category | Substantive Data |

|---|---|

| Energy Density | Traditional lithium-ion batteries: approximately 150-250 Wh/kg; carbon-based supercapacitors: 5-10 Wh/kg |

| Charge/Discharge Rate | Li-ion: hours to charge; supercapacitors: seconds to minutes |

| Cycle Life | Li-ion: 500-2000 cycles; supercapacitors: over 100,000 cycles with minimal capacity loss |

| Manufacturing Complexity | High for batteries due to chemical processing; relatively lower for carbon capacitors due to physical storage mechanisms |

| Scalability and Cost | Batteries benefit from mature supply chains; carbon systems are emerging with potential for low-cost scalable production |

Comparative Analysis: Energy Density and Efficiency

Energy density measures the amount of energy stored per unit weight or volume—a critical factor influencing application viability. Traditional lithium-ion batteries boast a high energy density, enabling portable electronics, electric vehicles, and grid storage to operate efficiently over extended periods. For instance, electric vehicle ranges hinge heavily on the capacity-to-weight ratio, with modern models reaching upwards of 370 miles per charge, as reported by industry standards.

Whispering in the wings are carbon-based systems like supercapacitors, which, despite exceptional cycle life and rapid charge capabilities, lag notably behind in energy density—typically an order of magnitude lower. This limitation constrains their utility for prolonged energy supply but positions them as ideal for applications requiring quick bursts of power, such as regenerative braking in EVs or power smoothing in renewable energy integrations.

Dissecting the Charge and Discharge Dynamics

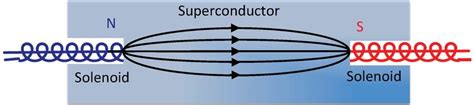

The kinetic profile of charge/discharge cycles reveals fundamental differences: chemical batteries store energy through ionic movement across electrodes—a process that is inherently slower, often taking hours for a complete charge cycle. Supercapacitors, through electrostatic storage mechanisms, can undergo thousands of rapid cycles with minimal degradation, transforming their role from energy reservoirs to quick-release power modules.

The implications for grid management are significant. Supercapacitors excel in frequency regulation and transient load balancing where response times are critical, whereas lithium-ion batteries are better suited for energy storage where prolonged discharges are necessary.

| Application Scenarios | Battery Power | Carbon Electric Charge Systems |

|---|---|---|

| Electric Vehicles | High range, moderate recharge times | Rapid acceleration, short-term power bursts, fast charging support |

| Grid Storage | Long-duration storage, energy smoothing | Frequency regulation, load balancing |

| Portable Electronics | Energy-dense, lightweight | Limited, but potentially faster charging accessories in future |

Environmental Impact and Sustainability Profile

Manufacturing traditional batteries involves complex chemical processes, including mining of lithium, cobalt, and other rare earth metals. These activities raise environmental and geopolitical concerns—ranging from ecological degradation to supply chain instability. Battery recycling technologies are advancing but lag behind the rapid growth of usage, posing waste management challenges.

Carbon-based systems, especially those utilizing abundant and recyclable materials like activated carbon, offer a more sustainable profile. Their fabrication involves less hazardous chemicals and can utilize waste biomass or other renewable feedstocks. Additionally, their operational longevity reduces replacement frequency, diminishing environmental footprint over time.

Potential Environmental Trade-offs

While supercapacitors excel environmentally, their lower energy density may necessitate larger physical sizes for the same storage volume, impacting material use efficiency. Furthermore, certain graphene synthesis methods involve energy-intensive steps, although ongoing research seeks to mitigate such impacts. Overall, their environmental advantages make them appealing for sustainable development initiatives, especially when integrated into hybrid power systems.

| Environmental Metrics | Traditional Batteries |

|---|---|

| Raw Material Toxicity | High (e.g., cobalt, lithium) |

| End-of-Life Recycling Rate | Variable; recycling infrastructure expanding |

| Carbon Footprint during Production | High, depending on chemical processes |

| Sustainability of Materials | Limited due to mining dependencies |

Technological Maturity and Industry Adoption

Traditional battery technology has matured over decades, achieving widespread industrial acceptance. The global lithium-ion market was valued at over USD 60 billion in 2022, with compound annual growth rates projected around 10% through the next decade. This maturity ensures consistency, supply chain robustness, and regulatory acceptance across multiple industries.

In contrast, carbon-based energy storage remains an emerging field. While preliminary commercial applications exist—such as supercapacitors in transportation and industrial sectors—the technology continues to evolve. Challenges include optimizing electrode materials, scaling manufacturing processes, and integrating hybrid systems to maximize benefits. Industry giants are investing heavily in research, signaling a trajectory toward broader adoption.

Industrial Challenges and Future Trajectories

One principal challenge lies in scaling laboratory innovations to mass production without sacrificing quality or significantly increasing costs. Additionally, interface stability, thermal management, and system integration present technical hurdles. However, the inherent scalability and potential low-cost manufacturing of carbon materials position them as promising candidates for a future where energy storage is not solely about maximizing capacity but also about enhancing responsiveness and sustainability.

| Adoption Trends | Traditional Batteries |

|---|---|

| Established supply chains, regulatory acceptance | High deployment in consumer electronics, EVs, grid storage |

| Emerging applications for carbon systems | Rapid growth in supercapacitor industry segments |

| Research Focus | Improving energy density, safety, and recycling |

| Research Focus | Enhancing capacity, stability, and cost-effectiveness |

Conclusion: Which Reigns Supreme? An Analytical Perspective

Deciding whether carbon electric charge or traditional storage methods dominate hinges on defining application priorities. For long-term, high-energy applications like electric vehicles or grid-scale backup, lithium-ion and similar chemistries sustain their leadership—benefiting from decades of refinement, extensive infrastructure, and high energy density. They excel where capacity over time is paramount.

Meanwhile, for applications demanding rapid response, high cycle durability, and sustainable profiles—such as power smoothing, emergency bursts, or decarbonizing transport—carbon-based systems display unparalleled strengths. Their rapid charging capabilities and minimal degradation over extensive cycles challenge the dominance of chemical batteries in niche but growing sectors.

What emerges is a landscape increasingly leaning toward hybrid modalities, where the future energy ecosystem gains from integrating these technologies’ complementary virtues. This approach crafts a resilient, efficient, and environmentally conscious energy infrastructure—each technology reigning supreme in its niche, yet converging for integrated optimality.