In the intricate web of urban infrastructure and water safety, backflow prevention emerges as a critical point of intervention. Ensuring that potable water remains uncontaminated requires not only diligent system design but also regular testing by qualified professionals—backflow testers. With myriad options available locally, the quest to find the best backflow tester near you today intertwines technical expertise, reputation, certification standards, and customer trust. This article explores the multifaceted landscape of backflow testing, offering an authoritative guide for consumers seeking reliable services to safeguard their water systems, and discusses how evolving regulatory frameworks and technological advancements shape the industry’s trajectory.

Understanding the Significance of Backflow Prevention in Water Safety

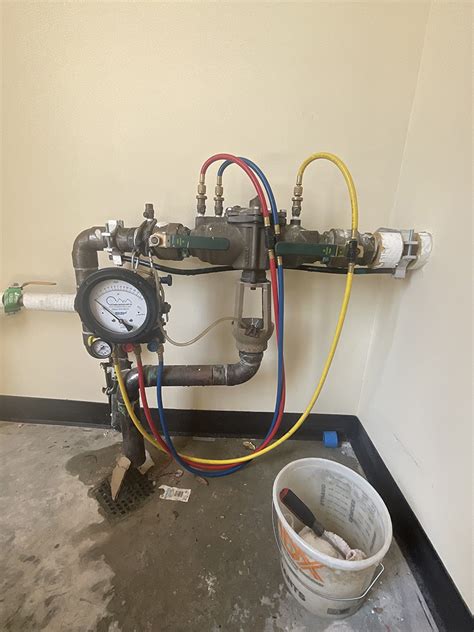

Backflow occurs when contaminated water reverses direction within a plumbing system, potentially polluting drinking water supplies. This phenomenon may result from pressure differentials caused by events like fire suppression system activations, sudden pressure drops, or cross-connections between potable and non-potable water sources. Effective backflow prevention devices—such as air gaps, reduced pressure zone (RPZ) assemblies, and dual check valves—serve as barriers hindering reverse flow. Regular testing of these devices is mandated by plumbing codes and health regulations because over time, mechanical parts may deteriorate, or installation imperfections could compromise their integrity.

The Regulatory Landscape Governing Backflow Testing

In many jurisdictions, local health departments or water utilities enforce strict compliance standards for backflow prevention. Certification and licensing of backflow testers play a pivotal role, ensuring that professionals possess the technical knowledge and practical skills necessary for accurate testing and maintenance. For instance, in the United States, certifications from organizations such as the American Backflow Prevention Association (ABPA) or state-specific licenses serve as proof of competency. Penalties for non-compliance or substandard testing can range from hefty fines to disconnection of water service, making the selection of a reputable tester not just advisable but essential.

Criteria for Selecting the Best Backflow Tester Near You Today

Locating a dependable backflow tester involves a combination of research, verification, and contextual judgment. Several key factors influence the quality and reliability of services offered:

- Certification and Licensing: Verify that the technician holds valid credentials aligned with state or local requirements.

- Experience and Reputation: Industry longevity, customer reviews, and peer recommendations provide insights into the tester’s competency and professionalism.

- Service Offerings: Comprehensive services, including testing, maintenance, repairs, and certifications, demonstrate a well-rounded operational scope.

- Availability and Responsiveness: Emergency response capabilities and flexible scheduling are valuable in urgent scenarios or routine check-ups.

- Affordability and Transparency: Upfront pricing with detailed estimates helps avoid unwelcome surprises.

Strategies for Finding the Best Backflow Tester Near You Today

Effective search strategies include leveraging online directories, consulting local plumbing associations, and evaluating customer feedback through review platforms. Key steps include:

- Using targeted search queries such as “Backflow Tester Near Me,” “Certified Backflow Testing Services,” or “Best Backflow Prevention Specialist in [Your City].”

- Assessing online reviews on Google, Yelp, or specialized plumbing service directories for consistency in positive feedback.

- Requesting quotes from multiple vendors to compare pricing, scope of services, and response time.

- Confirming credentials with licensing bodies or certification organizations.

- Seeking personal referrals from property managers, neighborhood associations, or fellow homeowners.

The Role of Technology and Industry Trends in Backflow Testing

Advancements in digital technology and industry practices are increasingly shaping backflow prevention and testing. Remote monitoring devices now enable early detection of backflow anomalies, reducing the need for frequent manual inspections. Moreover, data analytics facilitate predictive maintenance, optimizing device lifespan and performance. As jurisdictions adopt smart water management initiatives, local governments may offer digital portals for scheduling tests, submitting documentation, and verifying compliance in real time. Such trends emphasize the importance of choosing forward-thinking service providers who integrate innovative solutions into their offerings.

Impact of Digital Innovation on Service Quality and Trust

When selecting a backflow tester today, understanding their technological adoption can be a differentiator. Certified professionals utilizing digital testing equipment provide more accurate readings and documentation, streamlining compliance processes. This capacity not only boosts operational efficiency but also enhances transparency—customers can access test reports online, track maintenance history, and receive alerts for overdue inspections. As water safety becomes increasingly intertwined with smart infrastructure, the geographic proximity and adaptability of service providers to these technologies become essential markers of excellence.

| Relevant Category | Substantive Data |

|---|---|

| Average Cost of Backflow Testing | $75–$250 per device, depending on complexity and location |

| Certification Validity Period | Typically 1–3 years, requiring renewal for continued licensure |

| Detection Accuracy | Modern digital testers achieve >99% precision in identifying backflow issues |

| Customer Satisfaction Rate | Reliable providers maintain >90% positive reviews across platforms |

Conclusion

Finding the best backflow tester near you today demands a nuanced understanding that balances technical qualifications, reputation, technological adoption, and operational transparency. As water safety becomes increasingly prioritized amid urban density and environmental challenges, selecting a provider equipped with both experience and innovation ensures the integrity of your water supply. The landscape is evolving, with regulatory frameworks reinforcing standards and technological advancements facilitating smarter, more predictive maintenance. By scrutinizing credentials, leveraging modern search strategies, and valuing industry trends, consumers can confidently safeguard their water systems—today, and well into the future.

Key Points

- Certified, experienced backflow testers ensure compliance and water safety.

- Modern technological tools improve audit accuracy and transparency.

- Reputation, reviews, and professional affiliations serve as credible indicators.

- Strategic search approaches optimize local service discovery.

- Industry trends favor integration of digital diagnostics for proactive management.

How often should backflow preventers be tested?

+Typically, backflow preventers require annual testing according to most local regulations. However, some jurisdictions or specific system types may demand more frequent inspections, like biannual checks or after repair work.

What credentials should I look for in a backflow tester?

+Look for certifications from recognized bodies such as the American Backflow Prevention Association (ABPA), state licensing where applicable, and proof of ongoing training in modern testing techniques and equipment.

Can I perform backflow testing myself?

+While some advanced DIY kits exist, proper testing and maintenance require technical expertise and certification to ensure compliance and accuracy. Unauthorized testing can lead to regulatory penalties and unresolved system issues.

What are the signs that my backflow preventer might be failing?

+Signs include unusual odors, reduced water pressure, or visible leaks around the device. Regular testing helps catch issues before they compromise water safety.

How does water pressure affect backflow prevention?

+Pressure differentials drive backflow. Consistent proper pressure levels are vital; fluctuations can increase the risk of reverse flow, underscoring the importance of pressure regulation devices and timely testing.